Shotoku on TV

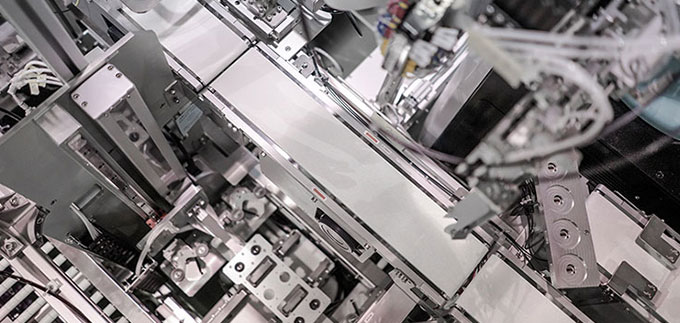

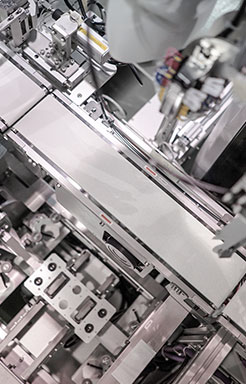

The word broadcast equipment may not sound familiar, but you may find our logo can be seen on many of the news, sports, and live broadcasts that you enjoy every day. Developed in-step with some of the world's highest quality broadcasters, we pride ourselves on the work we do. To find out more, click on the link below to visit shotoku.tv, our dedicated broadcast equipment website, or our dedicated rental service provider RentAct.